ConforMIS custom-made knee implants are designed to mimic every aspect of your natural knee – from its shape, to the way it bends and extends. We restore the natural shape of your unique anatomy, corrected for deformity, rather than replacing it with a pre-determined, standardized geometry.

Our innovative design allows for an implant that is thinner than traditional knee implants. A thinner implant can preserve more of your natural bone, which may be beneficial for future treatment options.1

Traditional, “off-the-shelf” knee replacements are manufactured in 6–10 standard sizes. During surgery, the surgeon selects the closest approximate size and makes necessary adjustments to fit the implant to your knee. The result is a replacement knee that is nothing like your own knee. This often can lead to pain or discomfort after surgery.

Multiple studies have shown satisfaction rates with iTotal CR well above the average of 80% seen in off-the-shelf knee patients.2,3

“When the [knee] pain became so severe I had to go to the hospital, I decided to do some research on the ConforMIS implants. I loved that they would be made just to fit me!”

According to Tedd Boomershine, the most important factor in his recovery was sticking with physical therapy. He would go four times per week at a nearby fitness center, walking to and from each time with his dog Stella. His first big test was on a vacation in Florence, Italy. There, Tedd climbed up 437 steps, which is something he couldn’t have done prior to surgery. He even went on a 20 mile hike one day!

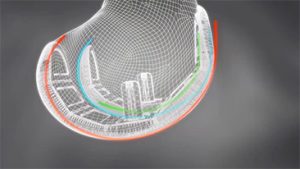

iFit Image-to-Implant® software is the technology platform that allows for the design of our patient-specific implants and instrumentation. Proprietary algorithms convert a CT scan of the knee to a 3D model by mapping the articular surface of the joint and defining the area of disease. That 3D model is used to design the implant and the surgical instrumentation that is unique to each patient.

To learn more about the benefits of iFit®—from design to manufacture to delivery—read below, or click the Learn More button.

ConforMIS implants and instruments are designed based on the patient’s CT scan. An automated design process uses proprietary algorithms to map the articular surface of the joint in three dimensions. The software uses that information to design the implants and instrumentation that will match precisely to the 3D model of the knee, correcting the data for any underlying arthritic deformity such as bone spurs, cysts or flattening of the joint.

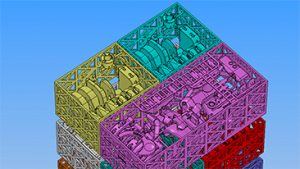

Our disposable, patient-specific iJig® instrumentation is manufactured using the latest in 3D printing technology. This allows us to develop patient-specific instruments for every step of the procedure.

ConforMIS is the only orthopedic company with just-in-time manufacturing and delivery capabilities. This means that our single-use kit is delivered a few days before surgery, removing the inventory from hospital shelves. This also allows for rapid design improvements that can be implemented immediately.

ConforMIS Knee Replacement technology gives surgeons the tools they need to treat their patients

Dr. Gary A. Levengood is the Founder and President of Sports Medicine South, LLC in Lawrenceville, GA. He is Board Certified in Orthopaedic Surgery and Sports Medicine by the American Board of Orthopedic Surgeons.

Of ConforMIS’ Knee Replacement technology, Dr. Levengood says, “I just sat there scratching my head, because I couldn’t believe that I could take a patient that was that far out of alignment and put him back into alignment without having to do a lot of extensive soft tissue work. And that patient was amazed too, because they didn’t think they’d ever see a straight leg again.”